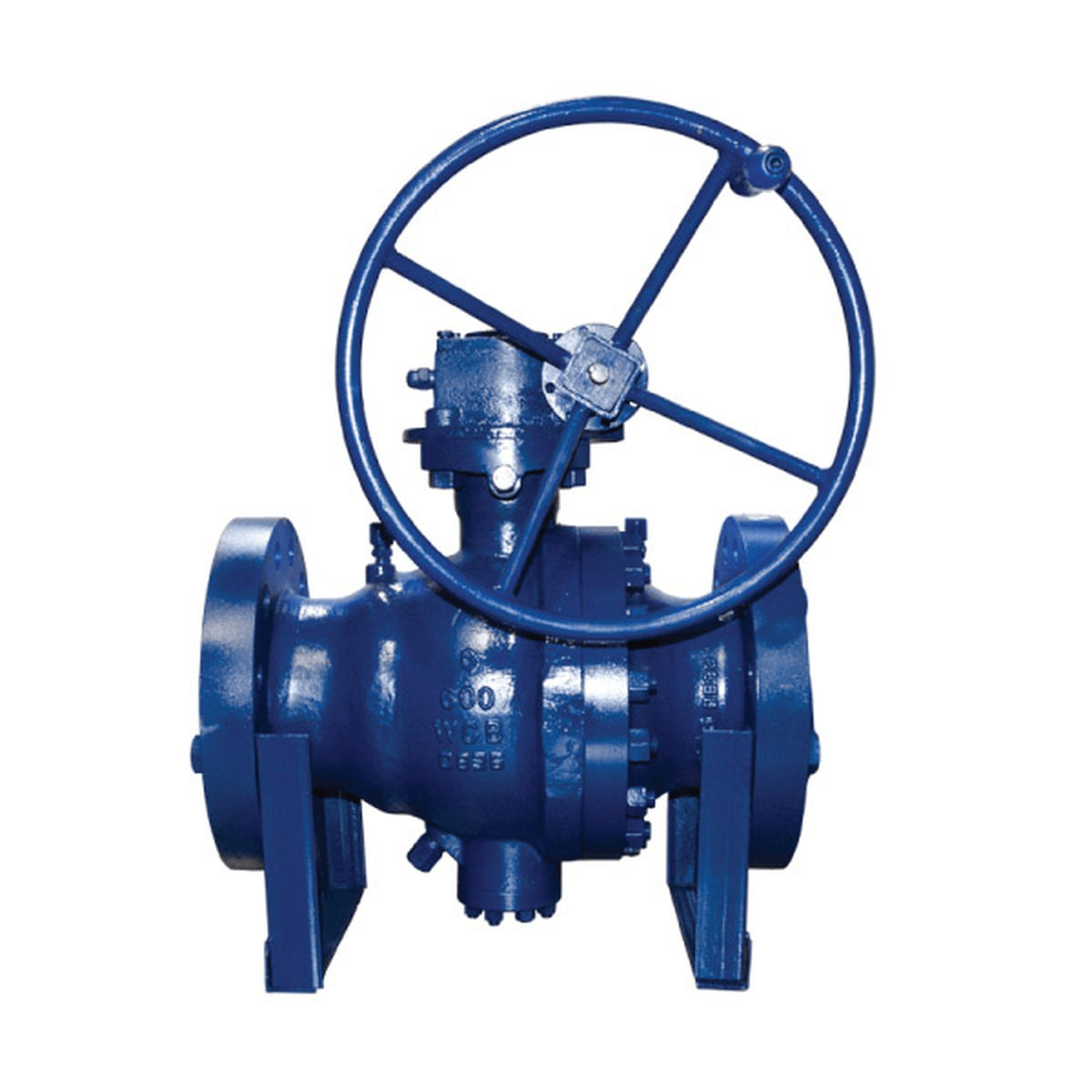

Floating Ball Valves for Industrial Applications

Floating ball valves are a widely used solution for controlling and isolating flow in industrial piping systems. The design uses a ball that is held in place by two seats but is not fixed to the stem. When pressure builds on the upstream side, the ball shifts slightly against the downstream seat, creating a tight seal. This simple yet effective mechanism makes floating ball valves suitable for a variety of industries across the United States, from oil and gas and chemical processing to water treatment, power generation and HVAC.

Benefits of Floating Ball Valves

Floating ball valves are valued for their dependable shutoff, simple operation and broad range of uses in industrial systems. With a quarter-turn mechanism, they open and close quickly, reducing downtime and simplifying maintenance. The floating ball design ensures a tight seal against the downstream seat, limiting the risk of leakage and helping to maintain process safety. They are versatile enough to handle water, steam, gas and chemical service, making them a practical option for industries that demand both reliability and efficiency.

Construction and Materials

Floating ball valves can be manufactured from a variety of materials, each suited to different conditions:

Carbon Steel: Common in high-pressure and high-temperature service, carbon steel offers durability and strength, making it suitable for oil and gas pipelines and heavy industrial systems.

Stainless Steel: Known for its corrosion resistance, stainless steel floating ball valves are often chosen for chemical plants, food processing and marine service where exposure to harsh environments is a concern.

Forged or Cast Bodies: The valve body may be produced by forging or casting. Forged valves generally provide higher strength and are often used in demanding service conditions. Cast valves are common where larger sizes and more complex designs are required.

By offering both stainless and carbon steel options in forged or cast construction, floating ball valves can meet a wide range of industry needs.

Applications Across Industries

Floating ball valves are widely used in many industrial systems because of their versatility and reliable sealing. In oil and gas, they provide safe shutoff in pipelines and processing units. Chemical and petrochemical plants rely on them to handle corrosive fluids, while water treatment facilities use them for consistent flow regulation. They also play an important role in power generation systems and HVAC networks, where simple operation and dependable performance are essential for day-to-day operations.

Choosing the Right Floating Ball Valve

When selecting a floating ball valve, consider these factors:

Material: Choose carbon steel for strength in high-pressure systems or stainless steel where resistance to corrosion is important.

Size and Pressure Rating: Ensure the valve matches your pipeline requirements and system conditions.

End Connections: Options include threaded, flanged and welded ends, depending on the installation design.

Operation Method: Manual operation is common, but valves can also be automated with electric or pneumatic actuators.

Shop Floating Ball Valves

Check our range of industrial floating ball valves to find the right match for your project. Trupply offers durable, high-quality valves designed to perform reliably in a wide range of industrial applications across the United States.